HOME >> About us >> Industrial news

Abstract

As machine elements designed for multiple applications, rolling contact bearings can be exposed to very different and also challenging operation conditions.

Additionally, since bearings are standard parts, suppliers are interchangeable and it is necessary to constantly monitor both quality and technical performance.

Testing on test rigs is the most reliable method for product verification. This publication gives an overview of different testing methods, the required equipment and testing strategies. The main testing methods are for frictional torque or temperature and for endurance. Both have their justification depending on what is most critical in the associated application. Concerning testing equipment, two standard options provided by Elgeti Engineering GmbH will be discussed and compared with other common test rig concepts present in the market. A particular point of reference is the FE8 test rig which is described in DIN 51819 [2] and is very common for research on bearings in major technical universities. Finally,testing strategies for various cases are developed and explained.

Motivation

The main reasons for bearing testing are:

● Technical validation / supplier approval

● Comparative assessment (applies to different suppliers or to different production methods

● Continuous quality control for incoming or outgoing inspections

Due to the complexity associated with testing, suitable approaches and strategies are essential for balancing time, expense and benefits.

Testing methods

Among testing methods, one firstly has to distinguish between testing for frictional torque or temperature and testing for endurance. Friction and temperature testing can help understand the effect of various operating conditions on the frictional torque and the equilibrium temperature. Such tests can help to evaluate power losses due to friction which contribute to the overall system efficiency. As an example, the losses in individual bearing elements in the drivetrain of an automobile and hence the total efficiency of the drivetrain can be evaluated. This testing method can also be used to provide a quick evaluation of the quality standards of regular deliveries (incoming inspections) [1] and to identify performance limits. Finally, steady state temperature can be a performance limiting criterion for grease lubricated bearings.

Endurance testing is used in order to evaluate the bearing lifetime under sustained use. Testing can be used to validate if the performance of the bearing and the lubricant comply with the technical specifications or expectations. When switching to or acquiring a new supplier one typically needs to ensure that the performance of the new product is better – or at the least not worse – than the current supplier. An accelerated endurance test can provide a quick comparative assessment of different suppliers and help one to make an informed decision. An endurance test which extends beyond theoretical life rating can also provide a quick test for incoming inspection [1].

Test rig setups offered by Elgeti Engineering can be classified as standard and customized. A standard setup provides the most cost-effective solution for the evaluation of bearing quality and performance. These setups provide the possibility of simulating axial, radial or combined loads as shown in figure 1, 2 and 3 respectively. It is important to note that in the case of combined load applications, the axial and radial loads are not independent of each other due to the friction between the tooling and the housing. Therefore, pure axial or pure radial testing can be the preferred approach even if combined loads would be have to be expected in the related application.

Figure 1 : Axial load application

Figure 2 : Radial load application

Figure 3 : Combined load application

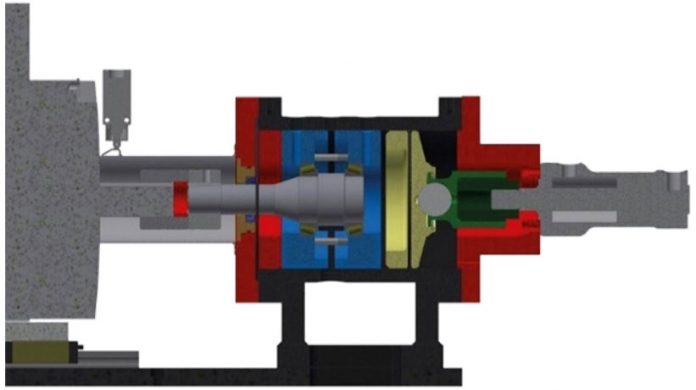

As compared with the standard test setups, customized setups by Elgeti Engineering permit a customized application of loads by which more realistic test conditions can be achieved. Figure 4 shows a multi-axial test rig which allows application of load with three degrees of freedom. This test rig is especially relevant for truck wheel hub bearings, pulley or planet bearings where apart from axial and radial loads, a tilting moment has to be simulated.

Figure 4 : Multi-axial load application

Testing Equipment

Standard test rigs all over the world use very similar main testing concepts. They are differentiated mainly based on the methods of temperature control and load application as well as the degree of automation. A compromise between cost and the required equipment precision as well as cost and the required statistical significance is necessary. More precise control and a higher degree of automation are accompanied by an increase in costs. Therefore, a test should be as simple as possible while being as complex as necessary. If high precision testing is too expensive, one is likely to do decline the service. In such cases, imprecise testing would still be the better option than no testing at all.

There are three major concepts for temperature control. No control at all results in the lowest cost. In this case, the ambient conditions are expected to be constant or at least repeatable. The second method of using 4 a heated housing is common for low speed application such as testing of lubricants in bearings at extreme mixed friction with the FE8 test rig according to DIN 51819 [2].

The third method, which is implemented on Elgeti Engineering test rigs, as shown in figure 5, provides complete and precise control of the degree of cooling and the oil flow rate and hence of the oil temperature. A closed loop control scheme is implemented whereby the rotational speed of the heat exchanger cooling fan motor is controlled according to the measured oil temperature (an average of inlet and outlet oil temperature at the housing). If necessary, the rotational speed of the pump motor can also be controlled. An optional heating device can be introduced into the lubrication oil circuit if operation if higher temperature is required.

Figure 5 : Temperature control and lubrication system

There are four major methods for load application. A crude load application can be achieved by using preloaded plate springs with washers, as is the case in the FE8 standard test rig. Although it is a very low-cost solution, it offers very low precision. Another method consists of a hydraulic transmission of load by using weights. This offers moderate precision compared to plate springs at an increased cost. This method is used in the majority of bearing test rigs available today.

Table 1: Comparison of load application concepts

A third method, which is implemented in Elgeti Engineering test rigs, uses hydraulic cylinders with a closed loop control of the hydraulic pressure. This method also offers moderate precision but at slightly increased cost over the previous approach. The major advantage over the previously mentioned methods is automation which allows the application of complex load cycles. Typical applications are smooth running in and automatic increasing of the load if there is no failure within a specified time.

The fourth method achieves higher precision by measuring the loads directly with load cells instead of measuring the hydraulic pressure. Elgeti Engineering test rigs are also compatible with this approach as shown in figure 6. The characteristics of the different load application methods are summarized in table 1.

Figure 6: Load control using load cell

Testing Strategies

Before developing particular testing strategies on bearing testing, one should firstly reflect the general kinds of testing by which bearing performance shall be assessed. Depending on the level of abstraction, tests can be classified as field tests, component tests, part tests and model tests.

Field tests involve testing of complete systems in real applications, e.g. test driving a car on a public road. This test is used to verify product behavior. Component tests involve the testing of aggregates on a test bench at defined operating conditions in order to assess their performance, e.g. testing a gearbox on an embracement bench. Part tests include testing of complete parts at defined conditions in order to verify the part’s properties, e.g. testing bearings on a bearing test bench. Model tests involve testing simplified specimens under defined physical and chemical influences, e.g. ball on disc tribometer. This type of test is mainly used for basic research purposes and product development.

The parameter trends of the various types of test are shown in the figure 7. The field test represents close to zero abstraction since the test takes place in a real application. This test is also highly complex, time consuming and expensive. The part test offers good level of abstraction for a bearing endurance or friction and temperature testing at a reasonable cost and complexity. This test is also precise and has highly repeatable testing conditions.

For endurance testing, statistical significance is an important topic as individual test results may vary greatly. Achieving a sufficient level of statistical significance is the main reason why bearing endurance has to be measured on a bearing test rig instead of a gearbox test rig despite the fact that the latter option is very common.

Figure 8 shows the result of ten lifetime test runs with the cumulative frequency of failure on the vertical axis and observed life in hours on the horizontal axis. The square boxes represent the results of individual test runs. In order to evaluate the lifetime of the population, a two parameter Weibull distribution is fitted to the plot (the solid line in figure 8). The parameter “a” is referred to as the scaling factor which represents the characteristic life and parameter “b” as the shape factor. These parameters are also liable to statistical variation depending on the samples.

Figure 7: Trends with respect to types of test

When taken in to account, this variation results in additional plots, shown as dotted lines in the figure 8. It can be concluded that the experimental L10 life of the population, when 10% of the bearings show the first evidence of fatigue failure, lies within certain limits defined by these plots of parameters variation. This interval size can be reduced by increasing the number of test samples. It is obvious that in most cases, gearbox test runs will be far too expensive for providing a sufficient data base.

In order to increase the statistical significance of testing, one has to consider a tradeoff between increasing the number of test runs and the precision of the test setup. The expense to increase the number of test runs is evident in terms of the increase in testing time whereas the expense to increase the precision of test setup is evident in terms of equipment costs. In some cases, particularly in academic applications, the higher precision offered by advanced equipment may be indispensible. For a standard test, the cost advantage of choosing to increase the number of tests instead of using expensive equipment may compensate for the disadvantage of increased testing time.

Figure 8: Cumulative Probability Distribution of bearing failure

The testing strategies differ depending on the motivation behind conducting the test. Tests can be conducted for supplier approval or technical validation, comparative assessment of endurance, or regular quality control.

Supplier approval may be necessary in order to reduce costs, shorten delivery time, improve quality and reduce risks. Supplier approval or technical validation can be addressed by validating the frictional torque behavior and endurance performance. Frictional torque or temperature testing tests are observed to be highly repeatable. Each test lasts for about a day including working time for setting up the specimens. In the case of an endurance test for technical validation, frequently five test runs are conducted with the following approach. In order for the entire batch to be approved, no failure must be observed in these samples until a test time of at least twice Ln,m (the modified test life according to ISO 281). In case of one failure, further test runs are required in order to reach a conclusion. In the case of two failures, the batch is not approved.

For a comparative assessment of endurance, test runs must be conducted until failure. The standard option involves conducting the test at steady state conditions, for example at half the dynamic load rating, for a given time and then subsequently increasing the load. Shaft bending should be avoided while increasing the load, as different bending would lead to different contact stress pattern and therefore to misleading results. A single test run typically lasts between two and four weeks. Accelerated performance tests provide the possibility to reduce the testing time to about one week while still being able to make a reasonable comparative assessment. In these tests, the load is continuously increased while avoiding shaft bending. This continuous increase of load can only be achieved on automated test rigs, as offered by Elgeti Engineering.

Apart from supplier approval, it is also important to ensure continuous quality control of deliveries. The incoming inspection is essential for the identification of non-qualified products prior to using them. For the supplier an outgoing inspection can prove to be beneficial for maintaining quality standards. In comparison to regular bearing inspection methods by visual appearance, geometry and material, inspection using test rigs can prove to be advantageous. In this test strategy, four randomly selected samples from each batch are tested at tough conditions until twice Ln,m (the modified test life according to ISO 281). This test could be completed within five days and at very limited costs. Although such a quick test is not sufficient for a precise evaluation of bearing performance, most common production and transportation faults that may mature to failure can be easily detected. Some of the flaws that have a high probability of being detected include poor material, geometrical deviation (detected during mounting on the test rig), hardening cracks, grinding burns, one rolling element of wrong diameter and mixing with low quality fake bearings.

Conclusion

Standard test rigs are very similar to each other concerning their basic concepts; yet, there are major differences in their approaches to temperature control and load introduction. Since testing is always a compromise between cost and accuracy, one must find a proper balance for each individual case – high level academic research must be clearly distinguished from the verification of moderate bearing quality.

While temperature and frictional torque testing typically yields repeatable results, the test results of life tests may vary considerably. Therefore, there is a trade-off between number of test runs that can be afforded and precision of equipment. For temperature and frictional torque testing, typically three test runs per population is sufficient.

For endurance testing, the following applies to the most common cases:

● 5 test runs until two times theoretic life for product validation

● 5 test runs until failure per population for comparative testing (here, one can apply either steady state conditions or increasing loads for accelerated performance tests)

● 4 samples (one or two test runs) at very tough condition until twice theoretic life for continuous quality control.

The last option is extremely powerful as it is quick and affordable for small size bearings. Testing can be done within one week leading to approval or rejection of a particular batch while removing the need for any other form of incoming or outgoing inspection – every major flaw that could be detected by geometrical or material inspection would most probably lead to premature failure during such tests.

References

[1] Bearing testing for incoming inspection, Elgeti Engineering Publication-2016-05-Bearing-testing-for-incoming-inspection.pdf, retrieved from https://www.elgeti-engineering.de/en/unternehmen/download/

[2] DIN 51819, 12/1999